Analysis of Pyrometallurgical Refining Process for Lead

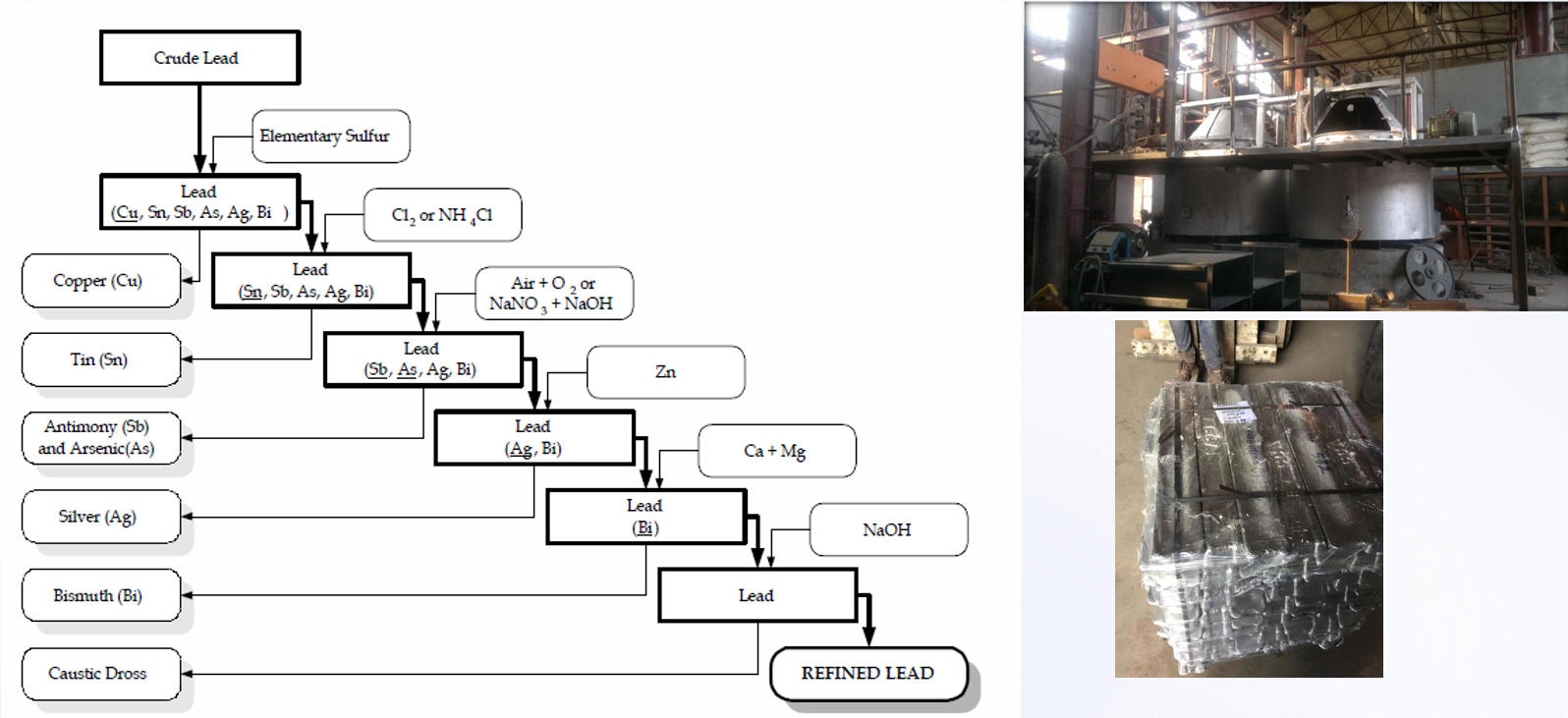

Pyrometallurgical lead refining is a critical process that uses crude lead as raw material to remove impurities and purify the metal through high-temperature metallurgical technology. This process centers on oxidation-reduction reactions, combined with steps such as liquation and slag formation, ultimately producing refined lead that meets industrial standards (purity ≥ 99.9%). The main steps are analyzed below from a professional perspective:

1. Raw Material Pretreatment System

A. Crude Lead Melting

Reverberatory furnaces or electric furnaces are used to melt crude lead within the temperature range of 480-520°C. The negative pressure inside the furnace is precisely controlled (-10 to -20 Pa) to prevent lead vapor escape. Impurities settle simultaneously during melting, with heavy metals like copper and antimony forming a slag layer.

B. Copper Removal by Liquation

A step-wise cooling process (350°C → 250°C) causes copper and its compounds (Cu₂S, Cu₂O) to crystallize and precipitate. Mechanical skimming devices continuously remove copper dross. After this step, the copper content in the molten lead can be reduced to below 0.02%.

2. Oxidation Refining Section

A. Alkaline Oxidation

Molten lead is transferred to refining kettles, and a mixture of sodium carbonate and sodium nitrate (ratio 2:1, 3-5% by weight) is added. Compressed air (pressure 0.3-0.5 MPa) is blown through the melt at 620-650°C. Impurities such as arsenic, antimony, and tin are oxidized into As₂O₃, Sb₂O₃, and react with the alkaline flux to form sodium salt slag: 3As + 5NaNO_3 \rightarrow 3Na_3AsO_4 + 5NO↑ + 6H_2O

B. Vacuum Dezincing

Vacuum distillation columns (pressure ≤ 100 Pa, temperature 750°C) are used to selectively evaporate zinc metal, achieving a condensation recovery rate of over 95%. The zinc content in the lead melt is reduced to the ppm level.

3. Reduction Refining System

A. Alkaline Reduction

Sodium hydroxide (2-3%) and glucose (0.5-1%) are added for reduction reactions to deeply remove residual oxides:

PbO + C_6H_{12}O_6 \rightarrow Pb + 6H_2O + 6CO_2↑

B. Flux Refining

A composite flux of zinc chloride and ammonium chloride (ratio 3:1) is used for final purification, effectively adsorbing trace impurities such as silver and bismuth, forming recyclable chloride slag.

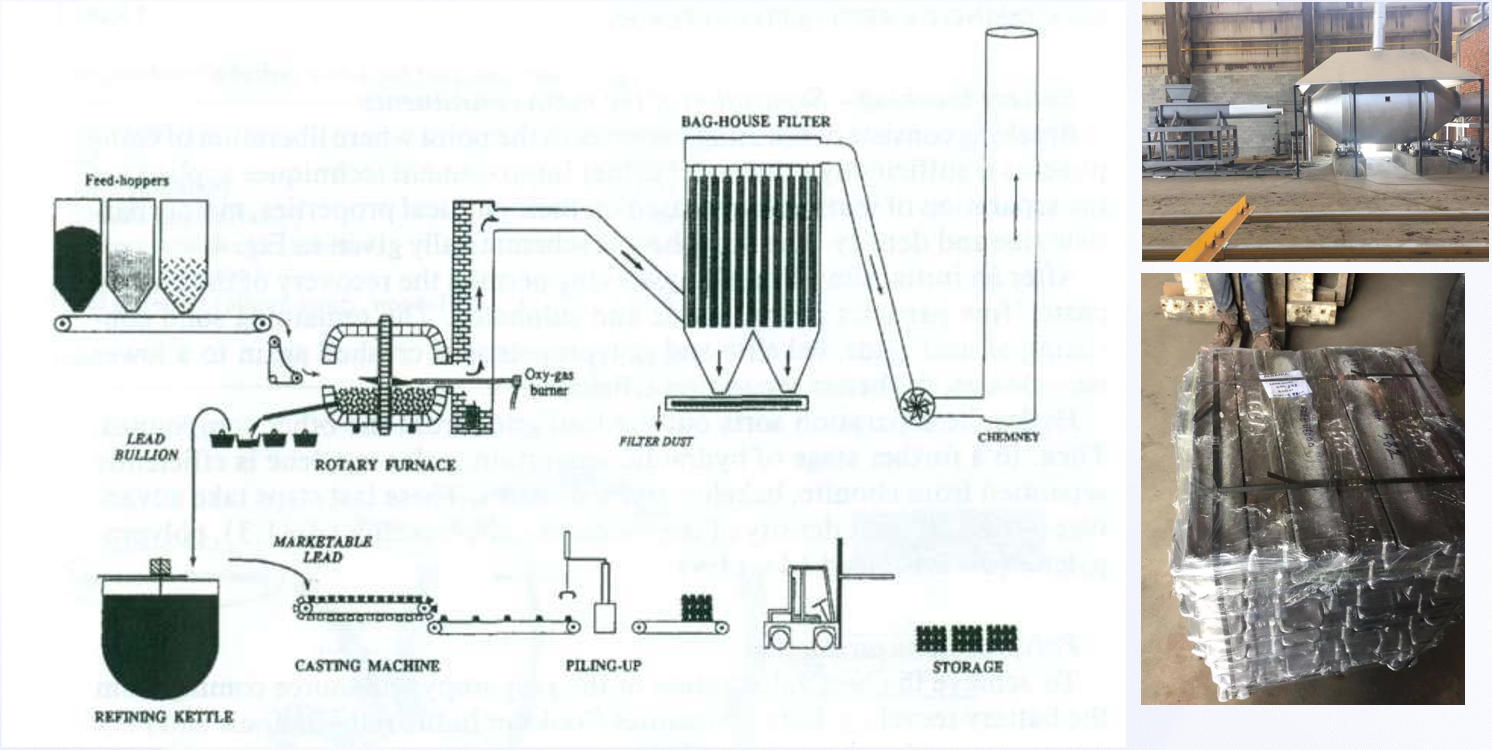

4. Ingot Casting Unit

A.Continuous Casting

The molten lead passes through a Insulated flow channel (temperature controlled at 400±5°C) into a double-band continuous casting machine, with the casting speed set at 8-12 m/min, producing standard lead ingots sized 1×0.5m.

B. Surface Treatment

A spray water cooling system (water pressure 0.15 MPa) is used for rapid cooling. The ingots are then treated in a shot blasting machine to achieve a surface roughness of Ra ≤ 3.2 μm, complying with ASTM B29 standards.

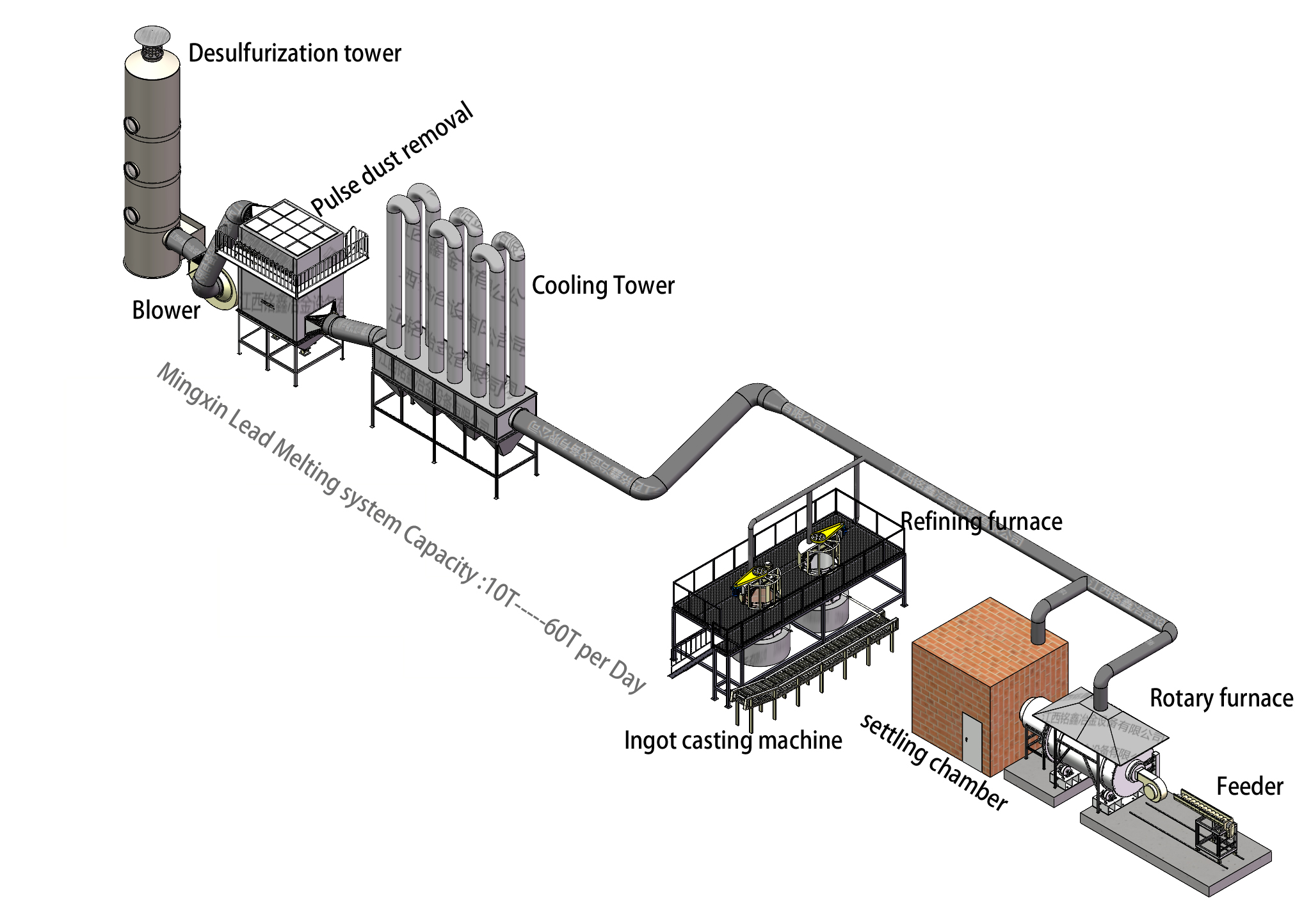

5. Environmental Protection and Resource Recovery

Flue Gas Treatment**: A three-stage purification system (cyclone dust removal + baghouse dust removal + alkaline scrubbing) is installed, achieving a lead dust capture efficiency ≥ 99.8% and an emission concentration < 1 mg/Nm³.

Slag Recycling: Copper dross is sent to copper smelting systems, and alkaline slag is treated by water leaching to extract sodium arsenate as a by-product. The comprehensive metal recovery rate exceeds 98%.

Process Innovation Directions

Modern lead refining is evolving towards intelligent operation, utilizing DCS control systems to optimize over 200 parameters in real-time, including temperature, pressure, and feed rate. The application of electromagnetic stirring technology (frequency 20-50 Hz) has increased reaction efficiency by 40%, and natural gas oxygen-enriched combustion technology (oxygen concentration 28-30%) has reduced energy consumption by over 15%.

Through precise phase control and clean production design, this process ensures lead quality while achieving green smelting, providing key material support for high-end application fields such as lead-acid batteries and radiation protection.

Analysis of Pyrometallurgical Refining Process for Lead-Blog-battery recycling machine,Jiangxi Mingxin

Analysis of Pyrometallurgical Refining Process for Lead-Blog-battery recycling machine,Jiangxi Mingxin