Structure and Working Principle of Lead Smelting Rotary Furnace|Kilns

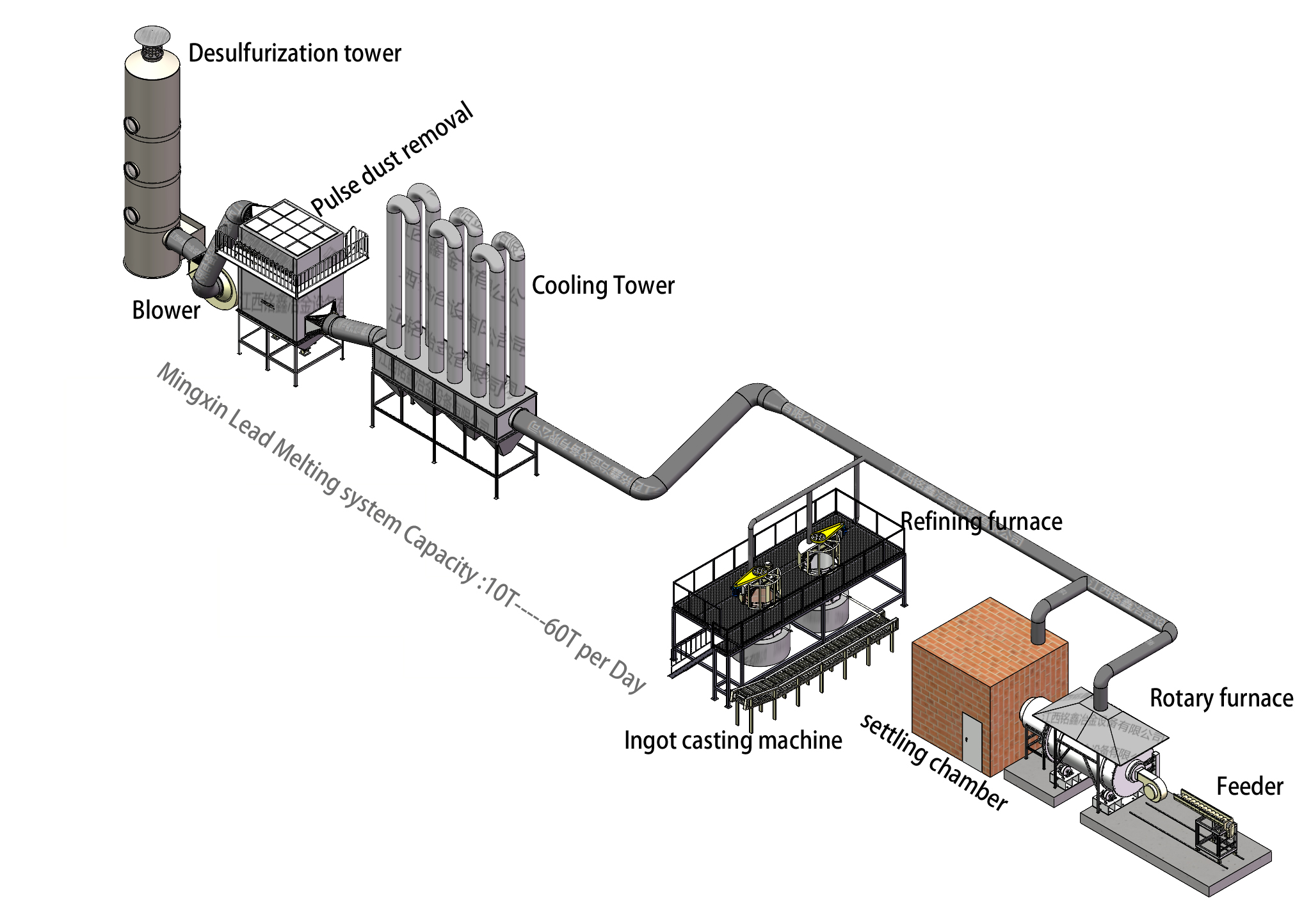

A rotary furnace is one of the most widely used and efficient technologies for lead smelting and refining. It is suitable for processing a wide range of lead-bearing materials such as lead scrap, battery grids, lead oxides, and dross. Compared with traditional blast furnaces, the rotary furnace offers better flexibility, higher metal recovery, and lower energy consumption.

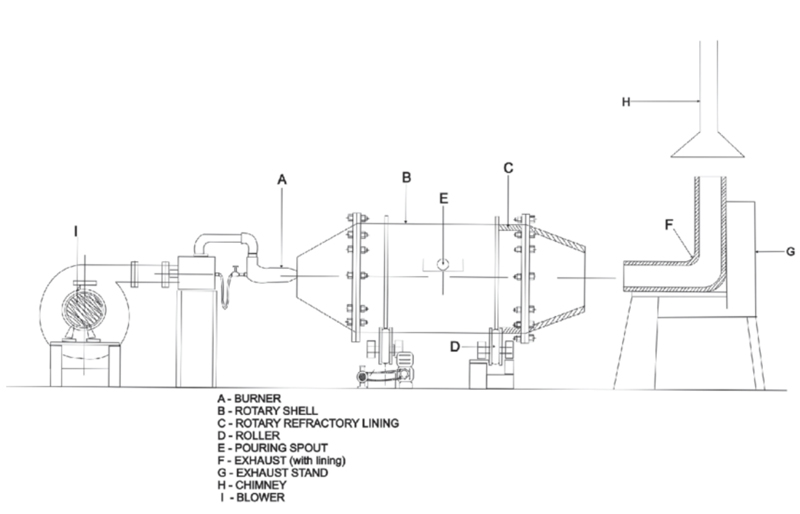

1. Structure Overview

The rotary furnace consists mainly of the following components:

Rotary Body (Refractory Lined Shell): A cylindrical steel shell lined with refractory bricks to withstand high temperatures and chemical corrosion.

Burner System: Usually fueled by LPG, natural gas, or diesel, it provides the necessary heat for smelting.

Drive Mechanism: A motor and gear system slowly rotates the furnace (typically 1–3 rpm) to ensure uniform heat distribution and material mixing.

Charging and Discharging Doors: Used for feeding raw materials and discharging molten lead and slag.

Air Supply & Exhaust System: Controls combustion and ensures efficient removal of off-gases through dust collection and filtration units.

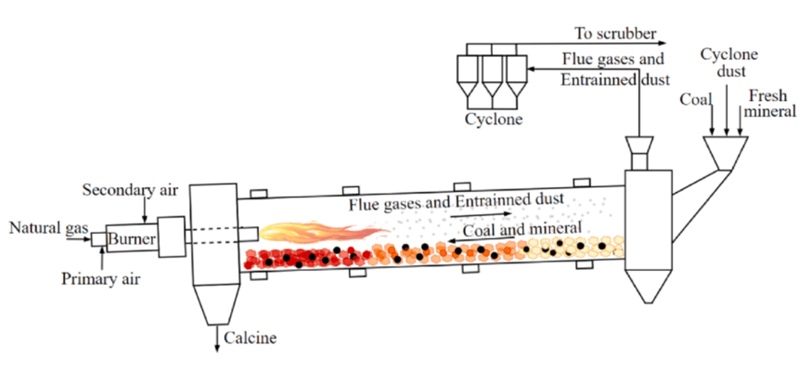

2. Working Principle

The working process of a lead smelting rotary furnace generally includes the following steps:

(1) Charging

Sorted and pre-treated lead materials (such as battery grids, lead paste, and slag) are loaded into the furnace together with a fluxing agent (like soda ash, limestone, or iron filings). The flux helps remove impurities and form a fluid slag layer during smelting.

(2) Heating and Rotation

Once the furnace is charged and sealed, the burner ignites to raise the internal temperature to around 1000–1200°C.

The continuous rotation of the furnace ensures that all materials are evenly heated and mixed, promoting uniform melting and chemical reactions.

(3) Reduction Reaction

Inside the furnace, lead compounds (lead oxide or lead sulfate) are reduced to metallic lead by carbon-based reducing agents such as coke or graphite.

The main chemical reaction can be represented as:

PbO+C→Pb+CO↑

Molten lead collects at the bottom of the furnace, while slag (containing oxides and impurities) floats above it.

(4) Tapping

Once the reduction is complete, the molten lead is tapped through a dedicated outlet and transferred to refining kettles for further purification. The residual slag is discharged separately for disposal or recycling.

3. Flue Gas and Environmental Control

During smelting, flue gases containing dust and lead vapors are generated. These gases are directed through a gas cooling system, bag filters, and scrubbers to remove particulates and harmful components before being released safely into the atmosphere—meeting environmental standards and ensuring operator safety.

4. Advantages of the Rotary Furnace

High Metal Recovery Rate: Up to 98% lead recovery from various raw materials.

Energy Efficiency: Rotary motion ensures even heat transfer and lower fuel consumption.

Operational Flexibility: Can handle a wide range of feed materials with varying moisture and composition.

Cleaner Operation: Closed structure reduces dust and emissions compared with conventional furnaces.

Conclusion:

The rotary furnace is a proven, efficient, and environmentally friendly solution for modern lead smelting operations. Its flexible operation, high yield, and ease of maintenance make it an essential piece of equipment for both primary and secondary lead producers worldwide.

Structure and Working Principle of Lead Smelting Rotary Furnace|Kilns-Blog-battery recycling machine,Jiangxi Mingxin

Structure and Working Principle of Lead Smelting Rotary Furnace|Kilns-Blog-battery recycling machine,Jiangxi Mingxin