Mingxin Lead Acid Battery Recycling Plant Introduction

1.1:Global lead-acid battery recycling status

The service life of the electrode plates of lead-acid batteries is generally 10 years in design, but the actual service life of lead-acid batteries is 1-2 years. Lead storage | The main cause of batterydeterioration is the accumulation of

lead sulfate deposits covering the electrode plate, which causes a sharp reduction in the chemical reaction area and leads to circuit blockage. In 2005, more than 200 million sets of lead-acid batteries were discarded in China, with millions of sets in general small and medium-sized cities, and tens of millions in large and medium-sized cities. The premature scrapping of lead-acid batteries not only seriously wastes energy, but also seriously pollutes the environment. Relevant international laws stipulate that waste batteries in various countries are not allowed to be shipped out,and can only be digested and processed by themselves, so the cost of disposing of these electronic wastes has increased a lot. Therefore, the daily maintenance and maintenance of lead-acid batteries, the recycling and reuse of waste batteries have become the focus of attention of governments and international groups.

1.2:Status of lead-acid batteries in developed countries

In developed countries such as the United States, Europe, and Japan, lead-acid batteries are widely used. In 2005, the global annual sales were 24.7 billion U.S. dollars, and the annual output in the United States reached 10.5 billion U.S. dollars, accounting for 1/3 of the global output. In developed countries, there is a set of extremely strict and standardized management systems for the production, sales, use, daily maintenance and maintenance of lead-acid batteries, recovery technology for waste batteries, recycling and reuse of waste batteries, and an industrialization has been formed. In the United States, there are millions of practitioners in the daily maintenance and maintenance of lead-acid batteries and the restoration and recycling of used batteries, and the annual benefits reach hundreds of billions of dollars. In Japan, there are hundreds of thousands of employees of lead-acid batteries, and the annual benefits reach tens of billions of

dollars. The future of China's electric vehicle market With the rapid development of my country's economy, transportation has also been greatly improved. As a new type of transportation newly developed in recent years-electric vehicles, there are many other transportation methods such as lightness, environmental protection, and economy. advantages not available.It is an undeniable fact that safe and environmentally friendly electric vehicles can replace motorcycles under the current pressure of traffic and environmental protection in largeand medium-sized cities in China; It is an irreversible market demand trend to replace traditional bicycles with perfect, more efficient, economical and practical electric bicycles.

1.3:The United Nations attaches great importance to the recycling of lead-acid batteries

The basic convention issued by the United Nations Environmental Protection Agency in 2003: <<technical guidelines for environmental Sound Management of Waste Lead-acid Batteries>>

2.Classification of waste lead-acid batteries

The large amount of lead-acid batteries involves a wide range of fields, which can be roughly divided into:

Waste car, motorcycle starter battery

Waste electric bicycle, electric motorcycle battery

Waste UPS battery

waste industrial battery

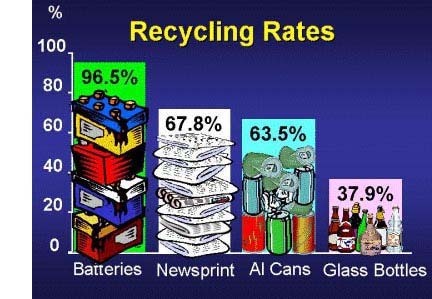

3.Lead-acid batteries are the waste products with the highest recyclable reuse rate

waste products with their recyclable reuse rate:

Lead-acid battery 96.5%

Newspaper 67.8%

Tin can 60%

Aluminum cans 63.5%

Tires 35.6%

Soft drink plastic packaging 25.2%

Plastic feeding bottle 31.9%

Glass containers 37.9%

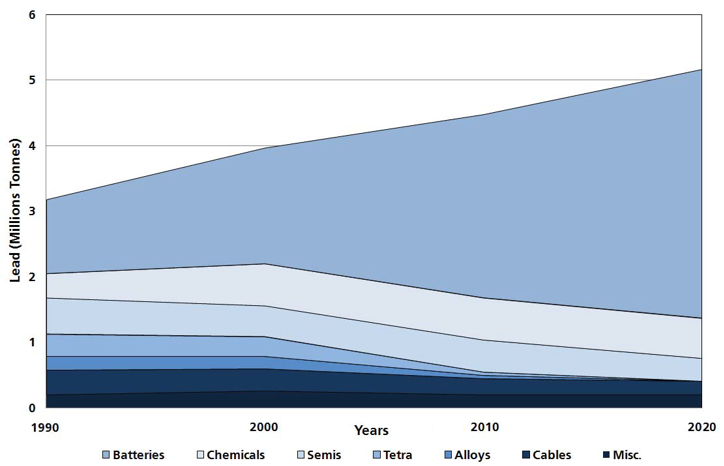

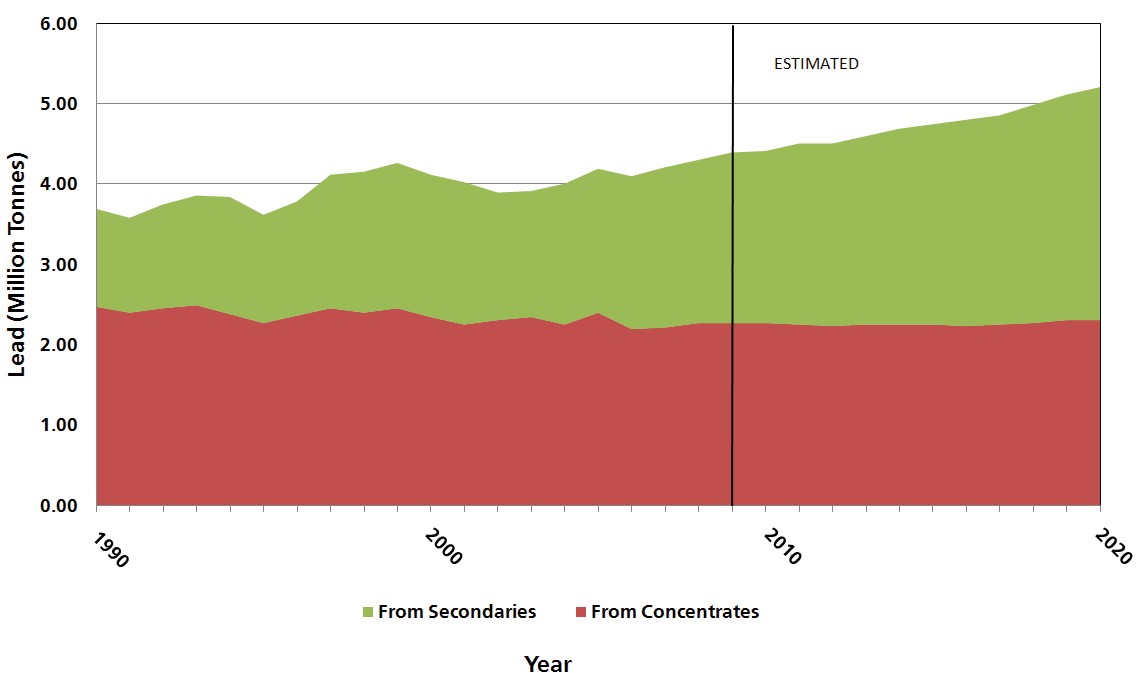

4.1 The recycling value of lead-acid batteries

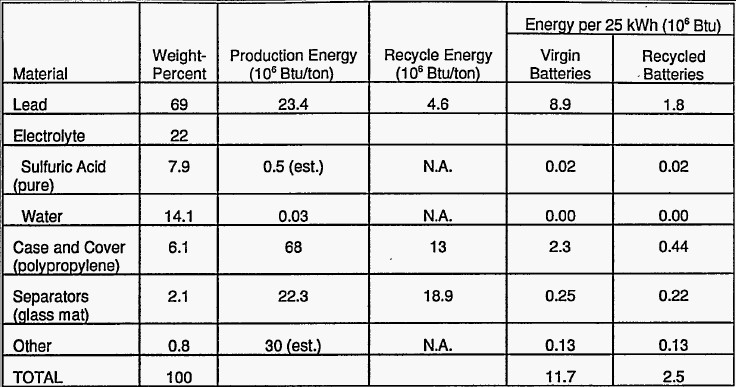

Recyclable material energy for lead-acid batteries

4.2 The recycling value of lead-acid batteries

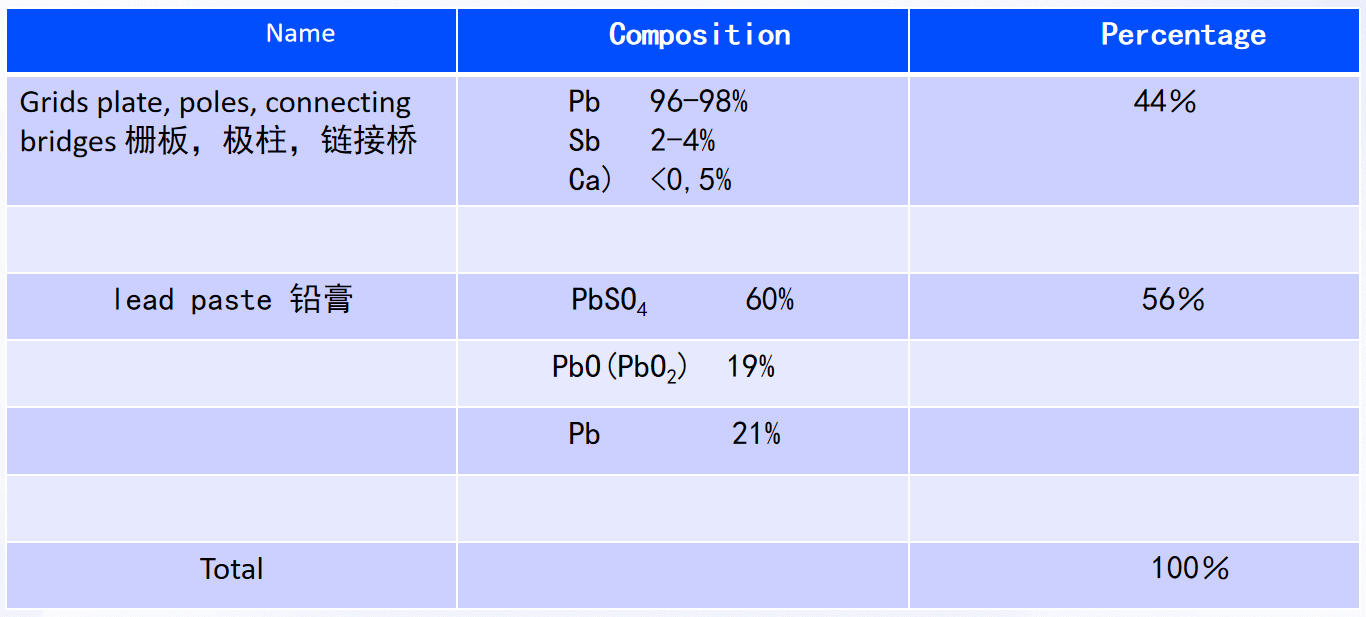

Proportion of recycled materials in Car Batteries

4.3 The recycling value of lead-acid batteries

Composition of lead-containing substances in waste Car Lead-acid Batteries

5.Mingxin Company Lead-acid Battery Solutions

At present, our company has designed a recycling process for waste lead-acid batteries, which is environmentally friendly, automated, and has a high recovery rate and can get the lead ingot purity above 99.97%, which roughly consists of the following systems:

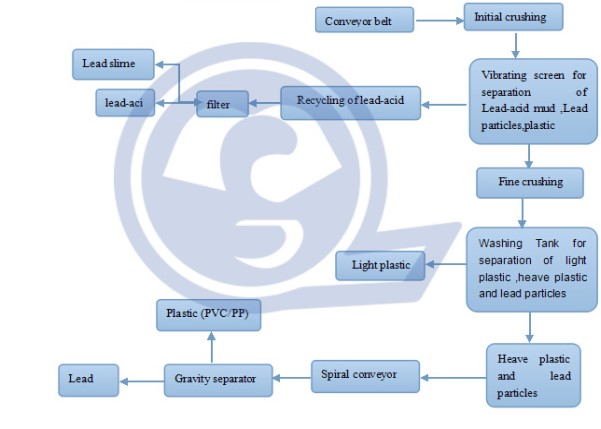

1.Crushing &Separating system

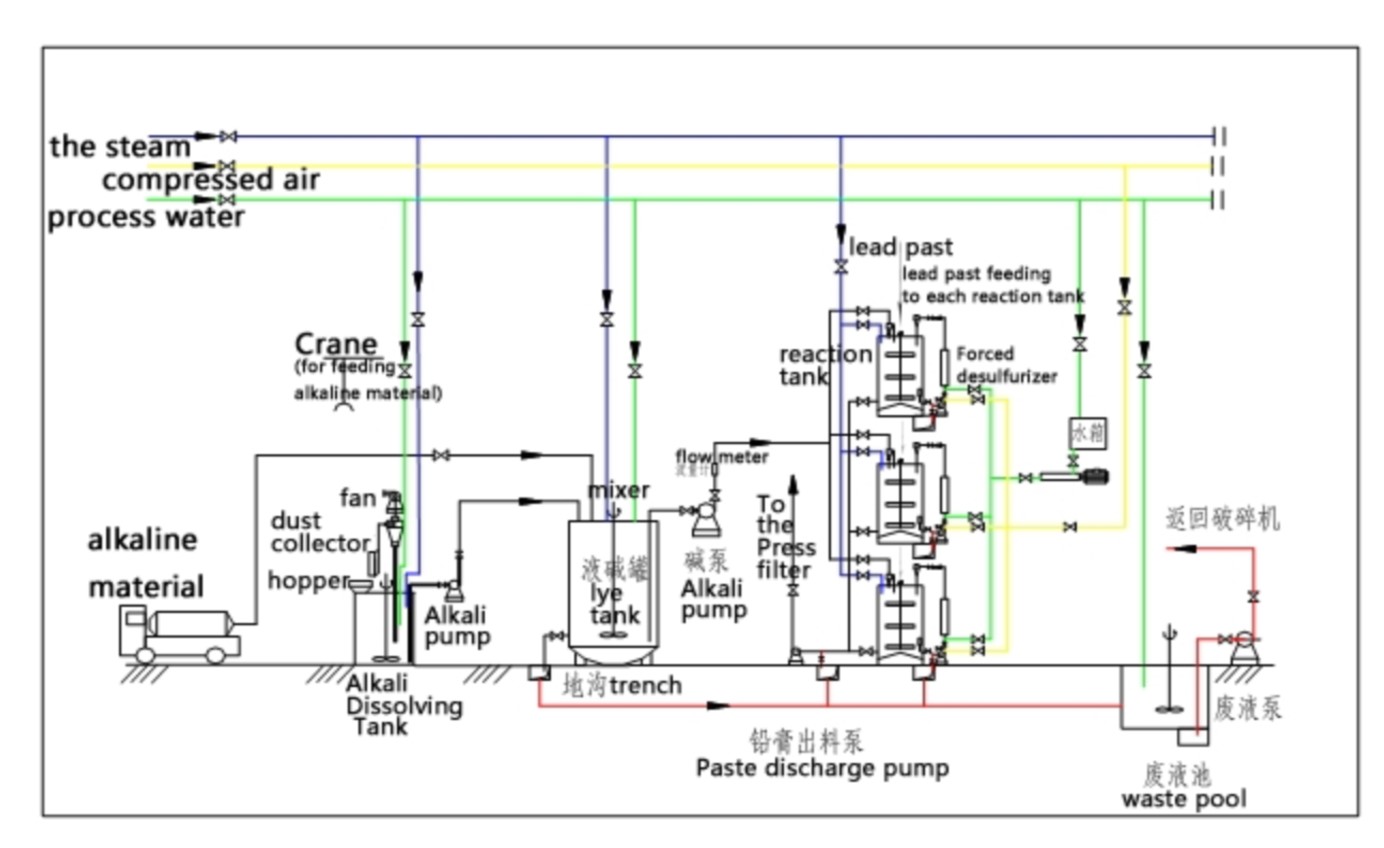

2.Desulfurization,purification, crystallization system (optional)

3.Melting system

5.1 Crushing &Separating Process flow:

5.2 Desulfurization,purification, crystallization system (optional):

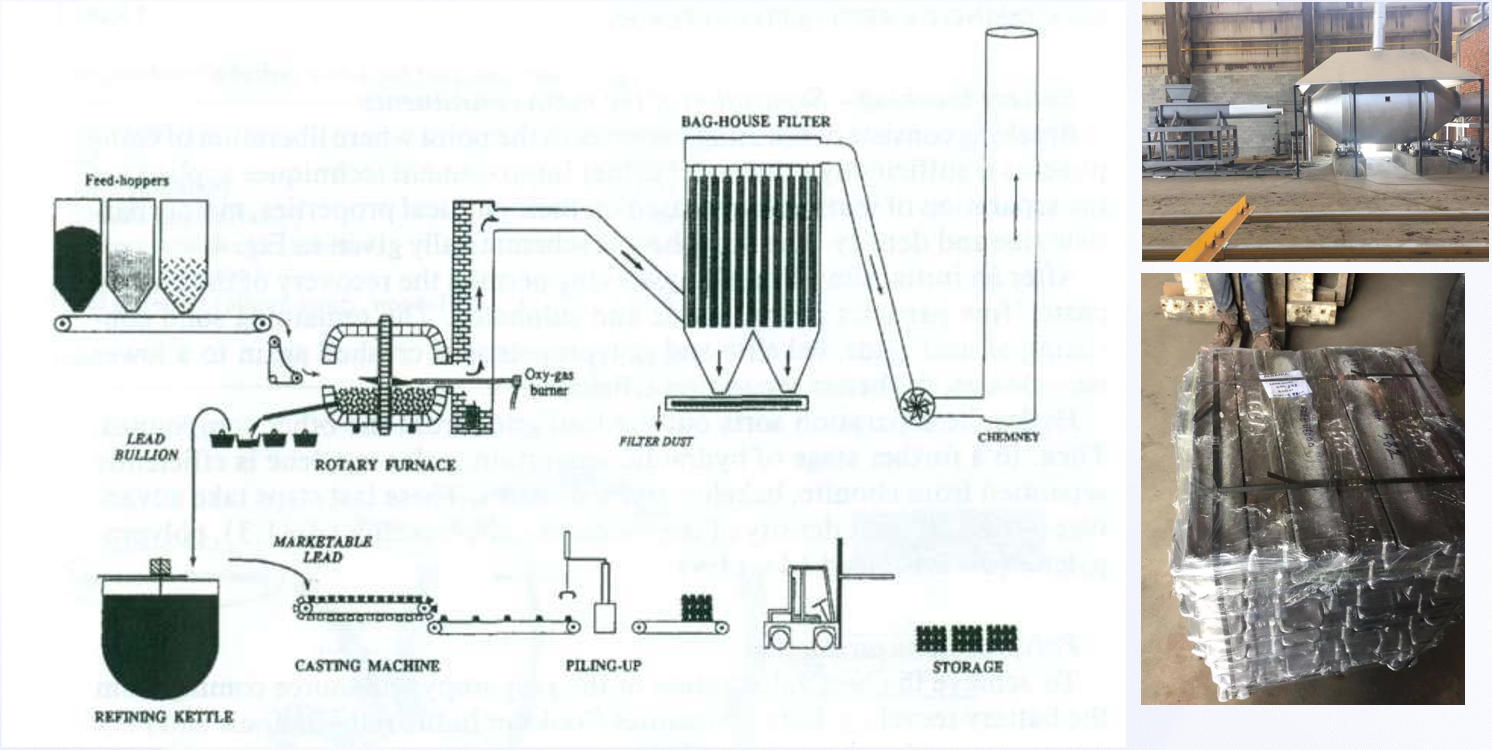

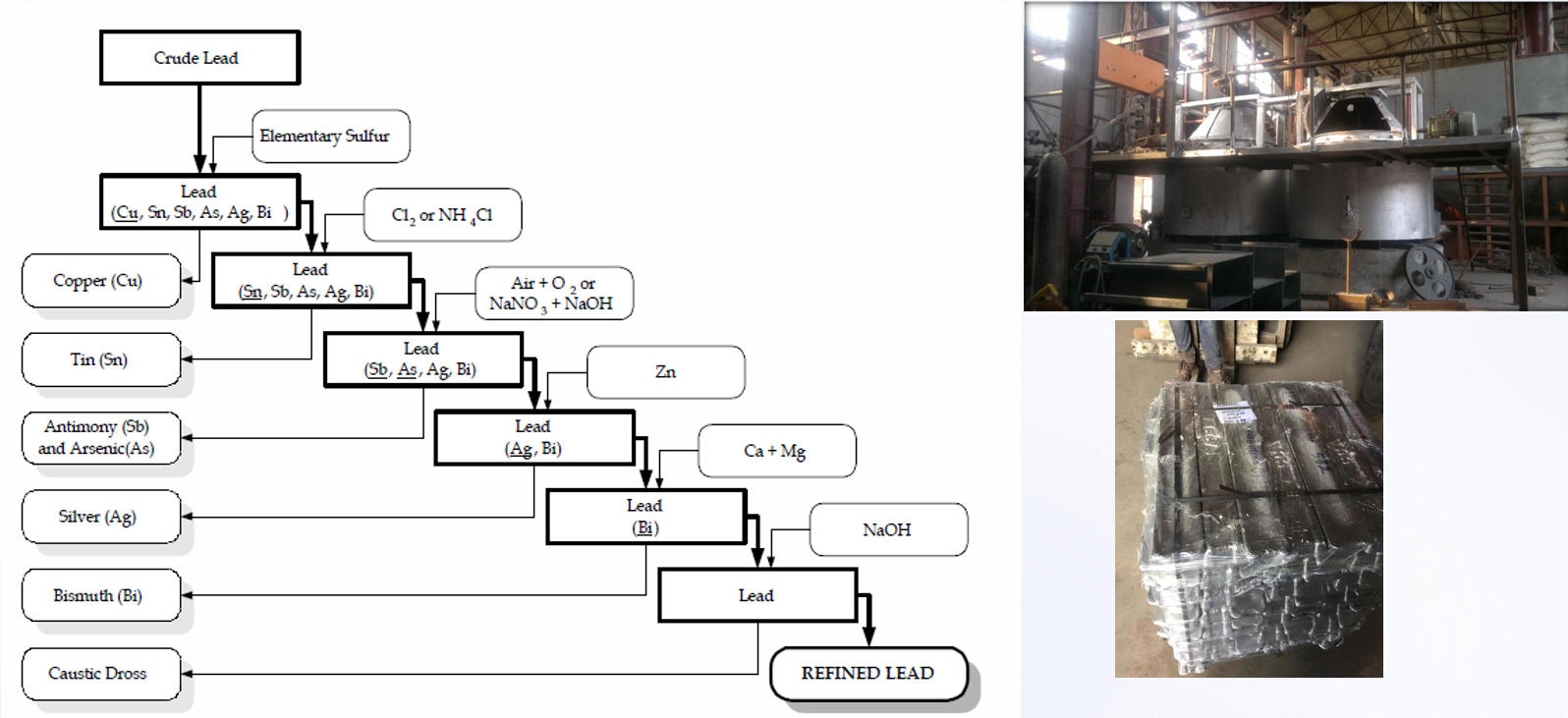

5.3 Melting system:

5.3.1 Refining process flow chart:

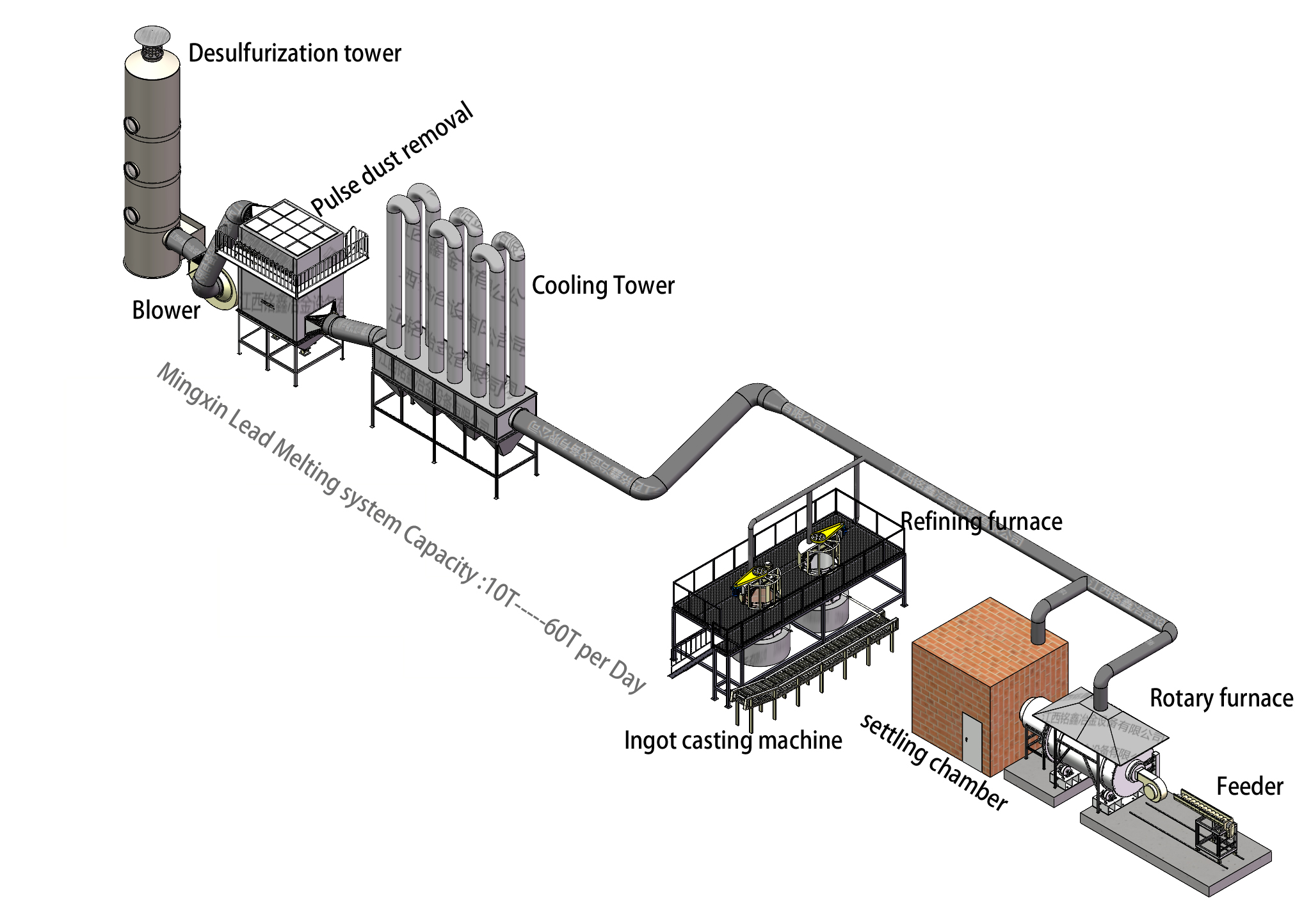

Here is the 3D layout of the lead acid battery recycling melting plant:

Here is the 3D layout of the lead acid battery recycling melting plant:

Mingxin Lead Acid Battery Recycling Plant Introduction -product-battery recycling machine,Jiangxi Mingxin

Mingxin Lead Acid Battery Recycling Plant Introduction -product-battery recycling machine,Jiangxi Mingxin